Automatic test of big

and complex boards

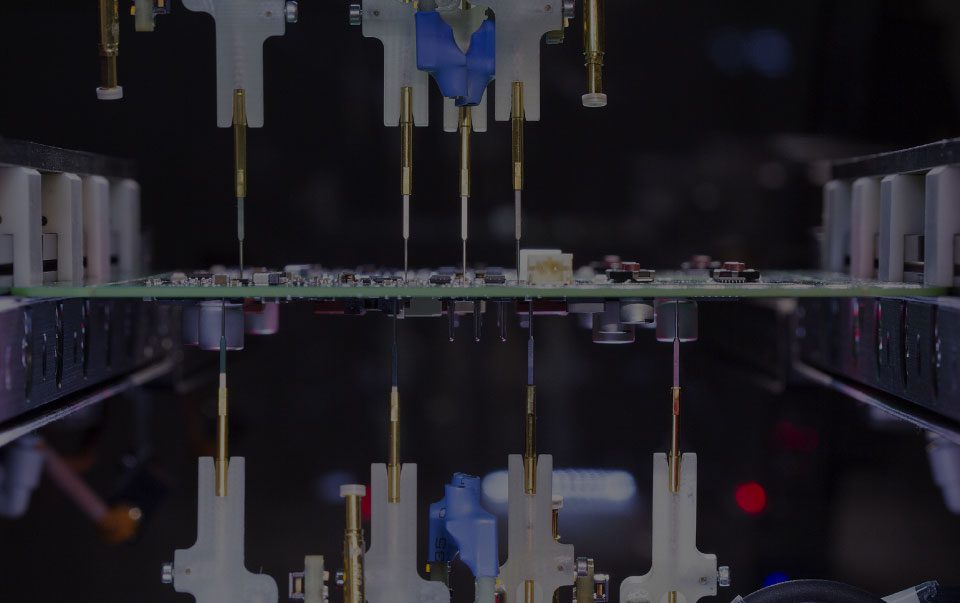

4080X is designed for the fixtureless production test of power electronic boards, including power inverters, power supplies, power drivers, and high-density SMD assemblies.

The system can automatically perform the conveyor handling of large and heavy boards (15kg and even more), then executes the accurate testing of electronic parts (digital, analog, power, running high-voltage test, supercapacitor test, polarity test, relay test) and mechanical parts such as magnets, LEDs and displays.

Moreover, additional operations such as optical inspection, flashing, RTC calibration can be performed on the same equipment used for electronic tests.

Advantages

Testing power boards with 4080X brings important advantages:

- Failure rate at the final functional test (end-of-line test) is close to zero

- Repair costs are greatly reduced by component-level diagnostics: repair engineers don’t need to struggle in finding failure causes

- Early failure detection reduces costs of unnecessary production operations on defective parts

- Functional/EOL test equipment can be simplified, final test time reduced

Features

Max. component height: 150 mm

Max. component height: 150 mm

The mechanical architecture of 4080X was designed to meet the testing requirements of electronic boards with components up to 150 mm tall.

No other flying probe tester allows you to test boards with components of this height, reaching even the inaccessible points for bed-of-nails systems.

Automated conveyor handling of big boards

Automated conveyor handling of big boards

- Operatorless working

- Direct integration in SMT line or test cells

Complete Test

Complete Test

- No defects at final functional/EOL test

- Field returns are practically eliminated

High Throughput

High Throughput

- Lowest cost of test

- Capability to respect SMT line takt time

Up to 180 touches/sec

Up to 180 touches/sec

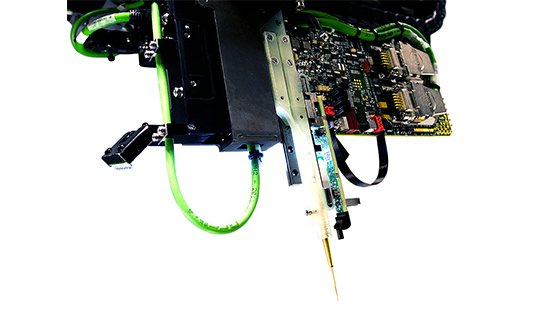

Full linear motion with linear optical encoders on XYZ axis provide very high acceleration and speed, along with positional repeatability and accuracy over unlimited travel.

Min. Pad size: 50 μm

Min. Pad size: 50 μm

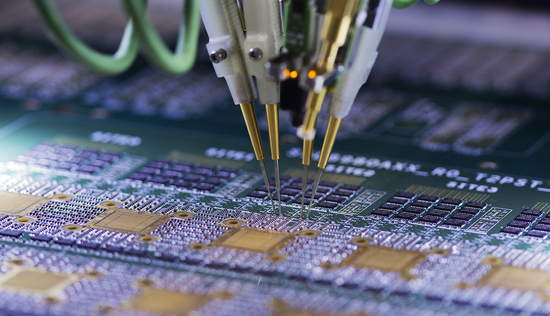

The highest positioning accuracy is guaranteed by sub-micron resolution Linear Optical Encoders on each XYZ axis, making 4080X suitable to touch 50μm pads at high speed and without leaving marks on them, like no other flying probe system can do.

Despite the speed, 4080X probes will touch the board softly. Programmable probing force makes the probes able to contact components at near-zero energy: even the most delicate electronics (ultra-fine pitch pads, sticky boards, flex circuits) can be tested with no risk of damage.

Full test coverage

Full test coverage

Full test coverage is provided by a complete range of test capabilities integrated in the 4080X, and by the highest available measurement accuracy offered by “Flying Tester Technology”: a complete forcing/measurement board integrated on each axis.

Natural granite chassis

Natural granite chassis

The natural granite chassis, combined with state-of-art linear motion technologies, offers low vibration and thermal stability, ensuring unprecedented probing precision at ultra-fast test speed.

Compared to conventional iron or steel, natural granite offers best damping characteristics and thermal stability, so to minimize vibrations and deformation effect that would affect accuracy and reliability through time.

Compact footprint: 2.4 m2 (25.83 ft2)

Compact footprint: 2.4 m2 (25.83 ft2)

4080X footprint is very compact: as little as 2.4m2, including in-line board transportation.

Suitable to replace bed-of-nails systems

Suitable to replace bed-of-nails systems

With a throughput that is three times (or even more!) higher than the fastest single-side flying prober on the market, the 4080X moves the ROI time of high volume productions to a level that is very close to the one of a traditional bed-of-nails tester.

Best Measurement Accuracy

Best Measurement Accuracy

- Highest measurement performance & accuracy (0.1pF)

- Signal integrity

- No measurement degradation or interference

- Immediate signal acquisition (within hundreds of microseconds)

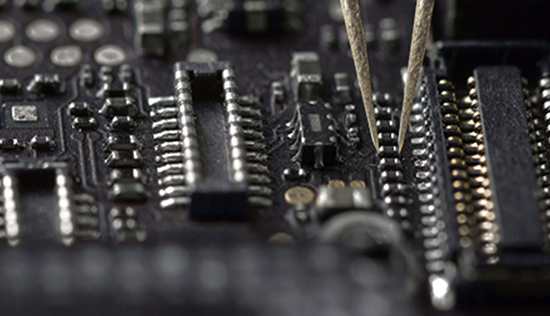

Up to 28 Top&Bottom Flying Tools

The 8 axes of the 4080X (4 top + 4 bottom) allow you to install up to 28 simultaneous flying test tools, within a range of more than 50 possible ones: in addition to the electrical probes, used to perform all the electrical tests, a variety of test tools are available to expand 4080X’s test capabilities.

Leonardo 4.

A world of Apps.

4080X users take the advantage of working with a friendly, appbased software environment, similar to what smartphones made us used to. Every app is dedicated to a defined function, while its update is independent and does not affect overall software integrity. Leonardo 4 operating system incorporates all the functionalities and effectiveness of previous Leonardo versions, bringing them a step ahead. In the world of apps you want to use.

Test Capabilities

In-Circuit Test

100% Short Circuit Test

Nodal Impedance Test

Open Pin Scan

Power On Test

Functional Test

Optical Test

Led Light Test

3D Laser Test

Flashing

Boundary Scan

Thermal Test

Waveform Capture

5G RF Test

Wafer Test

Built-In-Self-Test

Technical Data

| 4080X | |

|---|---|

| Max. component height: | 150mm |

| Application | Medium to Mass Production |

| Throughput | Top throughput |

| Chassis | Natural granite |

| UUT probing | Dual Side |

| Multi-Probe Flying Heads | 8 (4 top + 4 bottom) |

| Max. Board Size (L x W) | 1000 x 460mm (39.4 x 18.1”)* |

| Footprint (L x W) | 1700 x 1438mm (2.4m2) |

| * For larger boards, please contact SPEA. |