Battery Test

Complete testing of Battery Packs and Modules, with accurate measurements and verifications of electrical functionalities and mechanical parameters

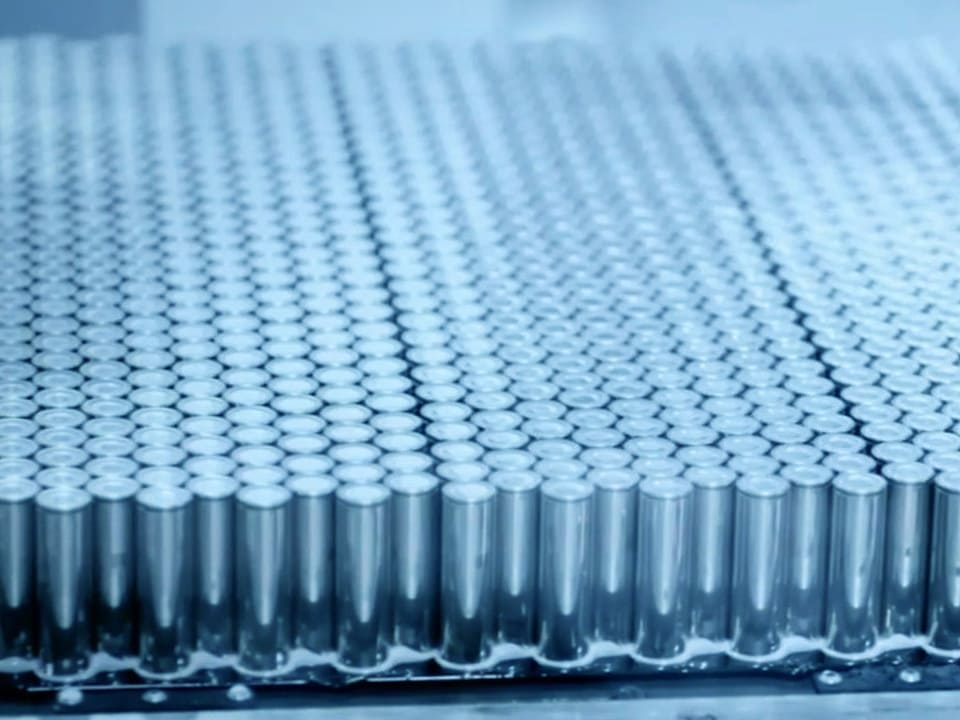

Batteries represent a key technology in a number of areas, including personal devices, transportation, industrial equipment. There are several challenges behind the need of ensuring the quality and performance of batteries, and a future device failure can often be predicted only with superior capability to detect small symptoms.

SPEA has been supplying the main manufacturers of batteries in the world, with equipment that is able to combine accurate electrical tests with very precise mechanical parameter verifications.

Electric Vehicles and Energy Storage Battery Test

Performance, durability and safety of battery packs and modules must be assured for every single unit produced. This can be possible only by testing them with automatic, high-throughput, flexible test equipment.

SPEA testers for batteries, based on the ultimate SPEA flying probe architecture, are able to measure, and verify, all the typical and characteristic parameters for battery packs and modules, including the quality of the cell wires welding, the internal battery resistance (both AC and DC), the Open Connection Voltage, just to list a few.

The test area is designed to accommodate the largest battery packs and modules, and includes auto alignment function of the module and automatic Z quote variation compensation, to ensure correct contact avoiding false fails.

Testing features on EV & Energy Storage Batteries

The measure of the cell wires resistance is performed using a high accuracy micrometer, with the capability to measure a few micro-Ohms in a few milliseconds.

Additionally, the kelvin probes can contact the battery using force-controlled actuators (5-2,500 g range), ensuring probing performance with no risk of damaging or leaving marks on the contacted surfaces. The equipment includes an accurate, laser-based meter to accurately measure the battery pack dimensions (length, width and height), identifying possible warpages generated during the module assembly process.

Tested battery packs and modules are transported by heavy-duty conveyors that can be set up either in pass-through or pass-back configuration.

Consumer Battery Test

Battery thickness and absence of deformations are verified with a top-class micrometer based on two precise parallel plates. These two plates move toward each other while maintaining absolute parallelism, in the order of a few ?m. Additionally, the module features a force-sensing capability while contacting the battery under test: during the thickness measurement, a programmable force in the range from 50 to 2,500 grams is applied.

Specific instruments are used to perform open circuit voltage and impedance measures.